Confined spaces

If you have any areas that:

Are large enough so an employee can fully enter and work,

Have restricted entry or exit, and

Are not primarily designed for continuous human occupancy,

You have a confined space, and you must identify them in your accident prevention program then evaluate each space as a potential permit-required confined space.

ALL confined spaces must be considered permit-required unless they have been evaluated and determined otherwise.

Permit-required confined spaces

A permit-required confiend space is confined space that has one or more of the following charactersistics capable of causing death or serious physical harm:

Contains or has the potential to contain a hazardous atmosphere;

Contains a material that has the potential for engulfing someone who enters;

Has an internal configuration that could allow someone entering to be trapped or asphyxiated by inwardly converging walls or by a floor, which slopes downward and tapers to a smaller cross-section; or

Contains any physical hazard. This includes any other recognized serious health or safety hazard including engulfment in a solid or liquid material, electrical shock, or moving parts.

Contains any other recognized serious safety or health hazard that could either:

Impair the ability to self-rescue; or

Result in a situation that presents an immediate danger to life or health.

If you have identified your spaces to be permit-required, you must have a plan to protect employees during entry.

-

-

-

Confined Space Identification Quick Reference

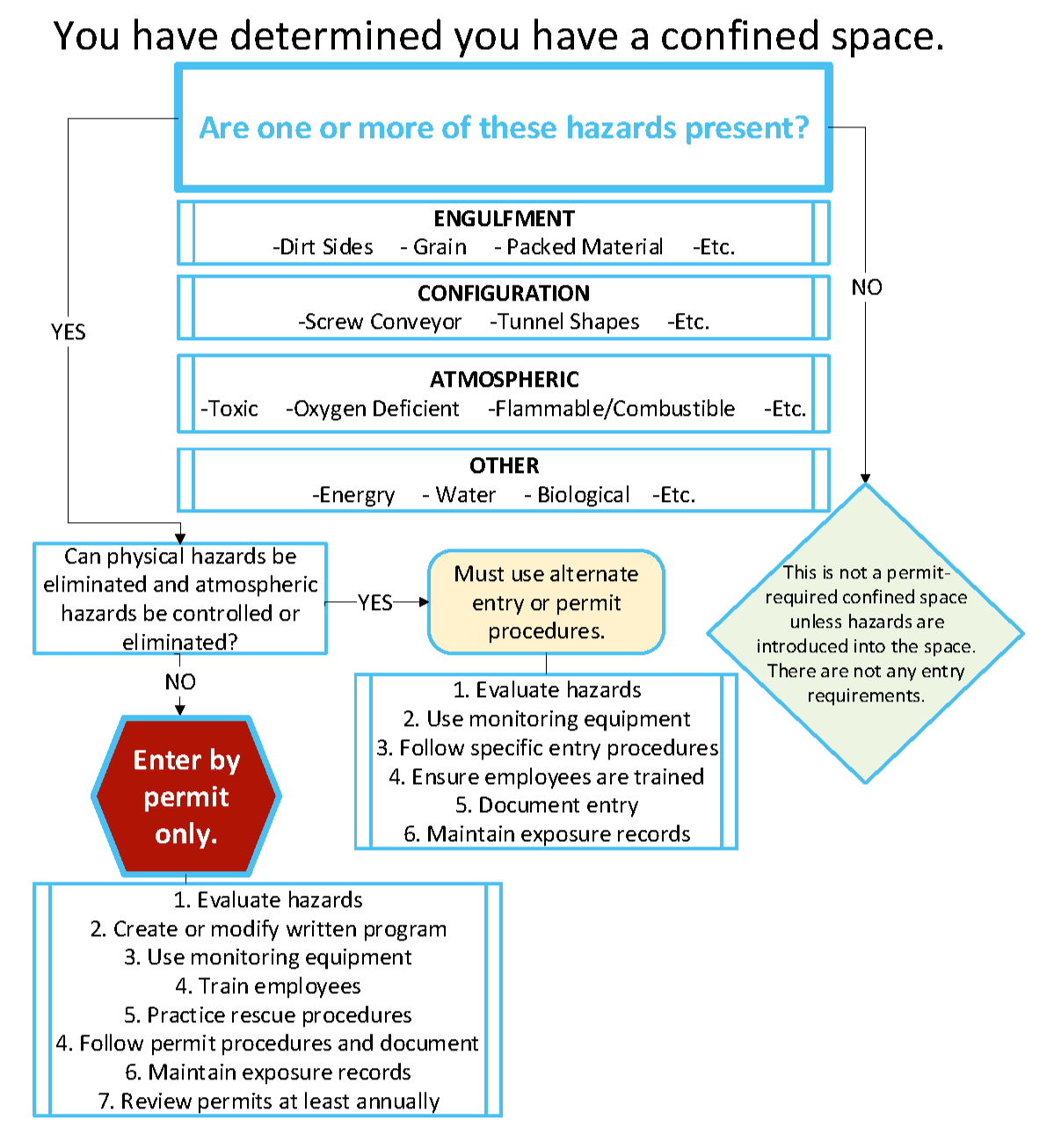

Permit-Required Confined Space Requirement Flow Chart

Atmospheric Testing or Monitoring in Confined Spaces

OSHA Fatal Facts: CSE on a Farm

Pesticide Spray Tank Entry Hazard Alert

Permit-Required Confined Space Sign

Examples

These are not comprehensive lists.

-

adhesive mixers

adhesive tanks

aggregate bins

air pollution equipment including Air Scrubbers

aircraft wing fuel tanks

aneraerobic digesters

attics autoclaves

bag houses

balers

bark blower

bar screen enclosures

bins blast furnaces

blast recovery pits

bleach tanks

boilers bridge box girders and enclosed beams

caustic soda tanks

caissons

cesspools and pits

chimneys and stacks

coal bunkers

cooling towers

chillers

clay hoppers

composters

compactors

controlled atmosphere (CA) rooms when sealed

concrete mixers

conveyor enclosures

crane legs

crawl spaces and attics

crude oil tanks crushers

cyclones

degreasers

digesters

dip tanks

dropped ceilings

dikes

duct work

dust collectors

drains

drums

drying ovens

excavations and trenches

fermenters

furnaces

garbage trucks

grease traps

heating and cooling ventilation

ductwork

hoppers

hydrapulpers

hydrogen reformer furnace

ice houses

incinerators

irrigation dam outlet towers

irrigation siphons

kilns

kettles

manholes

manure pits

mixers and mix tanks

mills ovens

pressure vessels

precipitators

pits

pipes and pipelines

rail tank cars

reaction and reactor veseels

reservoirs

sanitary

storm sewer and waste water systems

scrubbers

septic tanks

shafts

shredders

silos and hoppers

sludge pits

sulfuric acid tanks

tanks and vats

tanker vessels

tunnels vaults

water towers

wind machines

-

Processes that consume or displace oxygen include:

Activated charcoal

Rusting metal

Fermentation

Welding

Fires

Decaying organic material (and methane production)

Inert gases: argon (Ar2), carbon dioxide (CO2) including dry ice and chemical reactions producing carbon dioxide (CO2), helium (He2), nitrogen (N2). Some inert gases are used to control a potential flammable atmosphere. The inerting of the space with one of these gases will create an oxygen deficient atmosphere.

-

Enriched oxygen concentrations will increase the flammability of many materials including clothing.

Failure to inadequately blank or disconnect oxygen lines

Leaking oxygen hoses or pipes

Use of oxygen instead of air for ventilation

-

Be sure to review the exposure limits found in WAC 296-841 Air Contaminants. Additionally learn about Immediately Dangerous to Life or Health (IDLH) atmospheres here.

Ammonia Arsene

Carbon Monoxide (CO)

Burning or combusting fuels (incomplete combustion) for example: Gas heaters, stoves, and grills Portable generators Propane powered industrial trucks (forklifts) Internal combustible engines: vehicles, heavy equipment

Iron processing

Welding Poorly ventilated mines

Cyanide

Chlorine gas (Cl2)

Chlorine dioxide (ClO2)

Hydrogen Sulfide (H2S)

Oxides of nitrogen (NOX)

Carbon monoxide (CO)

Cleaning and degreasing chemicals: Hydrogen peroxide, Solvents, Halogenated degreasing agents like methylene chloride

Chemical reactions that result in the formation of toxic materials

Process chemical residues

-

Surrounding, suffocating, drowning, and bridging materials can engulf employees.

Water

Corn syrup

Chocolate

Wine

Beer

Plastic

Sewage

Grain

Sawdust

-

Internal configuration hazards include spaces with sloping walls or floors tapering to a smaller cross section trapping or asphyxiating a worker.

Silos

Hoppers

-

Biological hazards

disease causing organisms

poisonous spiders or snakes

Chemical reactions generating heat or reactive material (explosions, unstable or reactive materials).

Combustible dust and particulates

Energy

Electrical

Extreme temperatures

Falling objects, coke, scale, concrete, baled materials, tools and equipment)

Falls from heights

Flowable energy like steam, gas

Gravity

Hydraulic

Ignition sources

non-intrisically safe equipment (en exposed lightbulb in a flammable atmosphere)

Mechanical hazards

Metal dusts

Moving parts (augers, agitators, conveyors, crushers, tumblers, mixers, rakes)

Organic dust

Pneumatic

Pressurized lines

Radiation (Ionizing or non-ionizing)

Spark producing equipment and processes

welding

cutting

burning

torching

grinding

space heaters

static discharge

transferring liquids without bonding or grounding

Steam Stored energy

Systems under pressure

Water